OEM Sand Casting Parts with CNC Machining for Auto/Car/Truck Pump

Product Details

| Item | Auto/Car/Truck Pump |

| Surface Preparation | Sand Blasting, Plating, Galvanized, Spray-Paint, Passivating, Polishing, Electrophoresis, Machining, etc. |

| Surface Treatment | Shot blasting/Polishing/Painting/Powder coating/Anodizing/Zinc plating/Nickel plating/blacking, etc. |

| Surface Roughness | Ra0.05∼Ra50, depends on Customer’s Requirements |

| Heat Treatment | Normalizing, Annealing, Quenching, Tempering, etc. |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting tolerance | CT5-CT8 |

| Casting blank size | 2mm-1500mm or according to customer's requirement |

| Casting blank weight | 0.01kg-3000kg |

| Coating | Electrophoresis Coating |

| Machining | Lathing/Milling/Turning/Boring/Drillig/Tapping/Grinding, etc |

| Machining tolerance | 0.01mm |

| Design software/ formats | 3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T)/Soild Works/CAXA/Rhino/CATIA/SIMIO/ALIAS/ARENA/Unigraphics, etc |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Application | Automobile, Car, Heavy Truck, Light Truck, Commercial Vehicle , Forklift, Construction Machinery/Truck/Vehicle, Farm Vehicle/Machinery/Truck, Agriculture Machinery/Truck/Vehicle, Mining Machinery, etc. |

| Package | Bubble plastic bag/polybag/pallet/wooden case, etc. |

| Trademark | OEM |

| Origin | China |

| Loading Port | Qingdao Port |

| Annual Supply | 1000000 Pieces |

| Sample | Available |

| Sample production cycle | 30-45 Working days. |

| OEM/ODM service | Available |

Customized design and production

Provide whole engineering solution, covering material, process, finish etc.

Ductile iron(EN-GJS-400-18/450-10/500-7/600-3/700-2/800-2) and gray iron(EN-GJL-150/200/250/300/350) and so on. All available.

Precision machining, diverse heat treatment process and rich surface treatment(Galvanized/Powder coating/KTL(/EPD)/Dacromet/Geomet) available.

Application

1. Engine parts.

2. Auto parts.

3. Machinery Parts.

4. Rail Train parts.

5. Truck Parts.

6. Tractor Parts.

7. Construction Equipment.

8. Agriculture Equipment.

9. Other industrial fields.

Further Production Process

1. Machining equipment: CNC, Lathe machine, Milling machine, Drilling machine, Grinding machine, and so on.

2. Heat Treatment: annealing, carbonization, tempering, quench, normalization and surface tempering.

3. Surface treatment: Powder coating, Chrome plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, etc.

Tooling & Mould

1. Mould life: usually semi-permanent.

2. Tooling Leadtime: 15-25 days, depending on the structure and size.

3. Tooling & mould maintenance: Be responsible by Qingdao Syncretic Machinery Co., Ltd.

OEM and ODM service

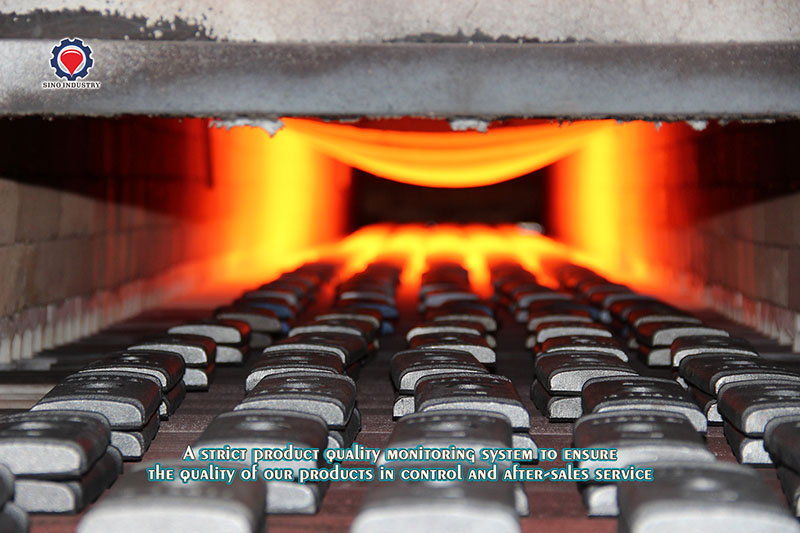

"No compromise" philosohpy in quality control.

110,000 tons per year of casting capacity, More than 40 years foundry history !

About us

Sino Industry and Trade Co., Ltd. (hereinafter referred to “SITC”) is a leading manufacturer of casting/forging/machining parts in China. Being one of major suppliers of customized parts for automobile/ machinery manufacturers spreaded all over the world, as well as China automotive giants FAW/ FOTON/ SINOTRUK/ SANY/ HOWO/ SHACMAN designated supplier for customization of auto parts, the company has been commited to offer high quality products with competitive prices and excellent service worldwide, and focuses on creating greater value for customers.

Superior production equipment, strict and effective quality assurance system, excellent and perfect detection means, rich technical force. Our goal is "Build an extraordinary brand ". More than 40 years experience in casting/machining industry, with 60 experienced technical engineers and 800 skilled workers.

We have passed the “ISO 9001” and “ IATF 16949” International Quality Management System Certification.

Pump Products Customization Service

We provide professional customization service for pump products, including auto/ car/ truck/ automobile/ automotive/ vehicle/ lorry water pump, pump body/ shell/ housing/ casing/ cover, as well as pump impeller, stainless steel pump, centrifugal pump, slurry pump, sewage pump, electric pump, submersible pump, high pressure pump, chemical pump, water pump set, self-priming pump, garden pump, deep well pump, oil pump, fountain pump, pond pump, mud pump, single suction pump, fuel pump, hydraulic pump, diesel pump, vacuum pump, etc.

Process introduction

- Integrated the advantages of forging and die casting.

- Parts forming under vacuum & high pressure conditions.

- Parts are made with very high density, very strong strength & hardness after T6.

- Roughness of parts are as same as the die casting.

- Precision with no more machining for some complex structure.

Why Choose us?

1. Own mould R&D team and mould making workshop.

2. Own factory to offer the reasonable prices and quick response.

3. Complete service from mould, production, heat treatment, surface treatment, assemble.

4. 40 years experience for die casting.

5. Squeeze casting+T6 -- to make the parts with lightweight and strong strength.

FAQ

1. Can we get free samples from you?

A. For the samples in our stocksize, sure, we'd like to provide you for free to check the quality, but hope you can bear the Freight cost.

B. For the customized samples, we can also open a new mould as your requests, but you have to bear this samples cost.

2.What is the normal lead time?

A. For stock products, we will send goods to you within 1~7days after receiving your payment.

B. For mass production, lead time is around 30~45 days, and longer if need open new mould.

3. Shipping

For bulk order,we can arrange shipment by sea or by air according to your requirement.

4. What is your payment term?

Usually we prefer TT and L/C, and the prepayment proportion is determined according to the order quantity, but mold and sample cost need to be paid in advance.

5. Do you accept the 3D drawings?

We accept 3D drawings. Software for specification drawings: Auto CAD, Solid work.

6.What about your quality?

All of our products have good quality. Each casting is processed through our QC staff with inspection records for every shipment. To guarantee the correct material specification and right mechanical properties, we have chemical analysis equipment, hardness tester, and tensile strength machine.

Advanced testing equipments, strict quality control system, to ensure us constantly, stably to provide high-quality products for customers.